The

Red Jacket® Submersible Turbine Pump (STP) is designed to efficiently

move fuel from underground storage tanks through piping systems to dispensing

equipment using controlled pressure energy. As a flagship Veeder-Root product,

it is engineered for reliability, safety, and ease of installation and

servicing. The 4” STP installs through a standard 4-inch tank opening and is

widely used in fuel retail, commercial, and industrial fueling applications.

Its advanced design optimizes fuel flow while reducing installation complexity and long-term maintenance requirements. The pump is supported by Veeder-Root’s global network of distributors and authorized service contractors, ensuring dependable lifecycle support.

Technical

Specifications (1.5 HP – 50 Hz)

This

submersible

centrifugal turbine pump is designed for reliable, continuous-duty operation in demanding fuel applications. It features a standard

4-inch threaded tank opening for easy installation and a robust 1.5 HP (1.13 kW) single-phase motor running at 2850 RPM on a 220/240

V, 50 Hz supply.

Built for safety and durability, the pump is explosion-proof (Class

I, Group D) and includes built-in automatic

thermal overload protection to prevent motor damage. Its multi-stage,

self-lubricating centrifugal design ensures efficient pumping with a 2-inch NPT discharge outlet.

Engineered to perform in challenging environments, it operates reliably within an ambient temperature range of -20°C to +51°C and handles product temperatures up to 40.5°C. The pump meets stringent safety and performance standards, certified by UL

79 and cUL approvals.

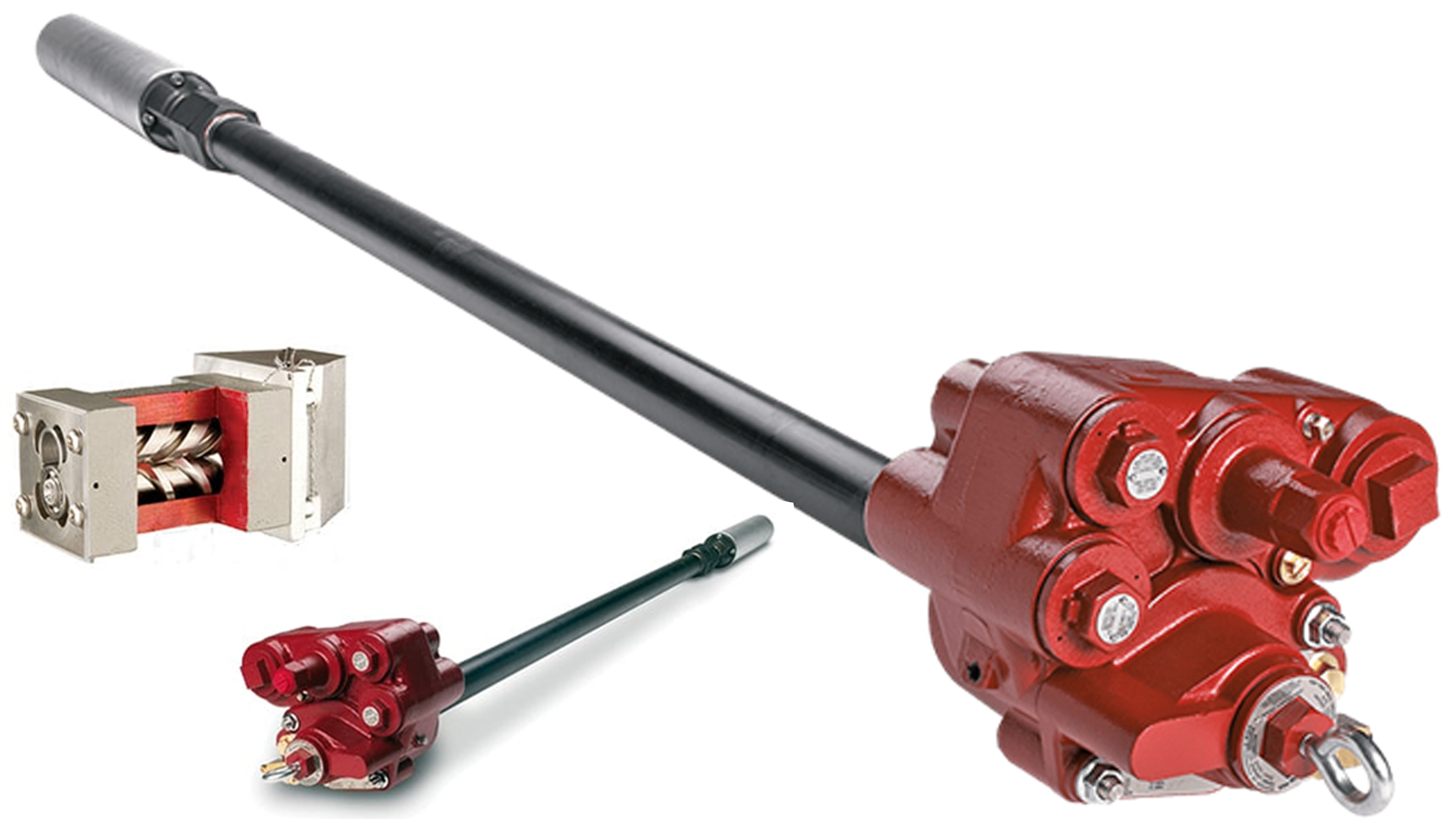

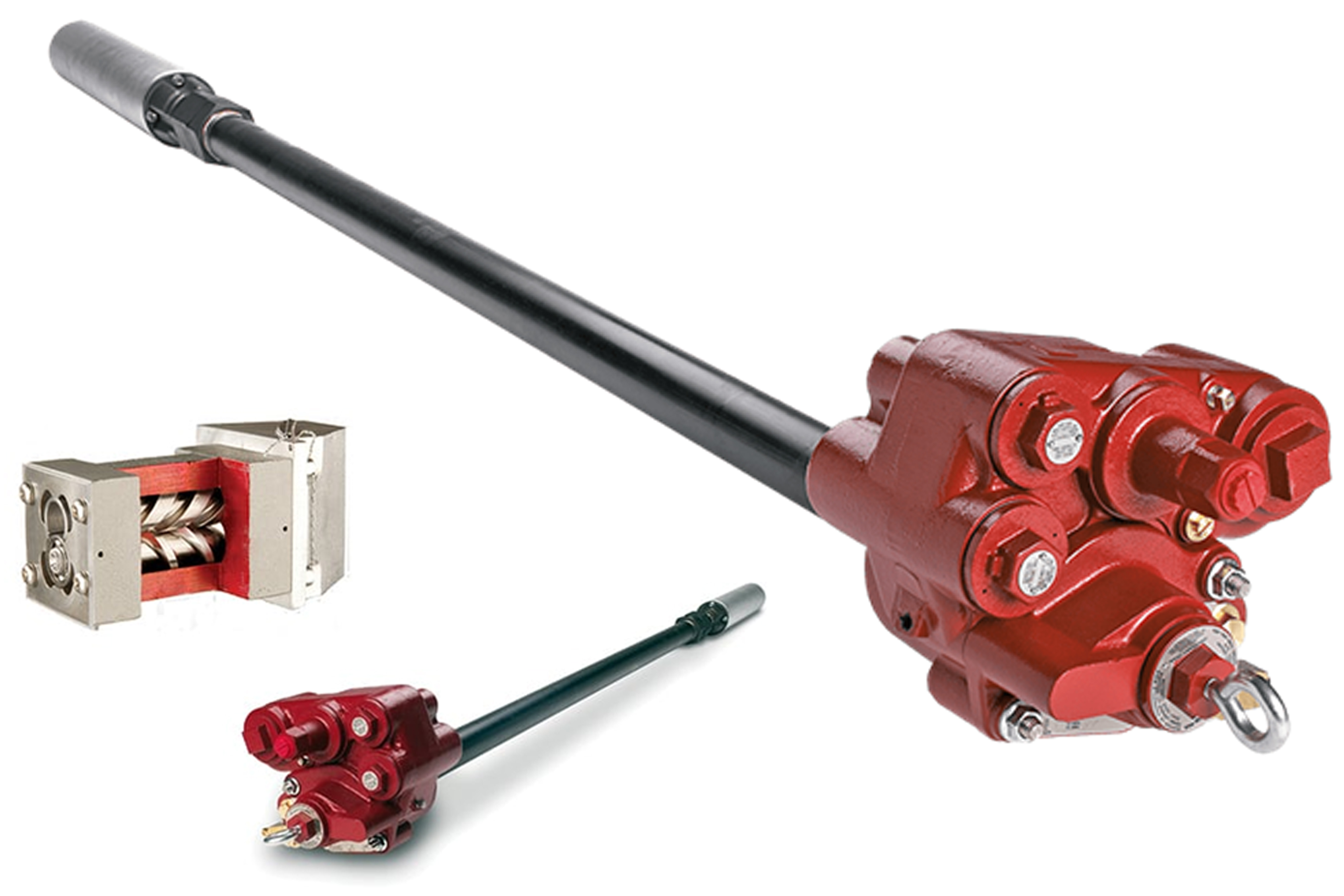

Mechanical & Design Features

The 4” Red Jacket STP uses a multi-stage

impeller and diffuser system to deliver stable pressure and high flow efficiency. Impellers are splined to the pump shaft to ensure positive, non-slip rotation, while diffusers are securely fixed to prevent movement and wear.

A horizontal pump intake minimizes sediment pickup from the tank bottom, protecting internal components and improving longevity. The pump and motor assembly can be removed as a unit from above ground, allowing fast servicing without disconnecting discharge piping, leak detection systems, or siphon equipment.

The extractable packer manifold

head assembly provides a complete seal against fuel leakage and water intrusion. It integrates key safety components including:

- Check Valve

- Pressure relief valve

- Air purge screw

- Support for single or dual vacuum sensor siphon systems

The Lock-n-Lift check valve system allows controlled depressurization of the line during servicing, safely returning fuel to the tank and preventing spills.

Electrical Features

The pump is powered by a hermetically

sealed, explosion-proof electric motor designed for hazardous fuel environments. The motor includes:

- Quick-disconnect electrical connectors for fast service

- Automatic thermal overload protection

- Sealed windings to prevent fuel or moisture ingress

Electrical disconnection is automatically achieved when the extractable packer assembly is removed, eliminating the need for swing joints or manual wiring disconnections.

Types & Configurations

The 4” Red Jacket STP is available in Quick

Set® adjustable length configurations, allowing one pump model to fit multiple tank depths. Lengths are adjustable on-site and can be resized in the future without replacing the pump assembly.

Configurations are available:

- With or without Floating

Suction Adapter (FSA)

- Across multiple adjustable length ranges to suit shallow and deep tanks

This flexibility significantly reduces inventory requirements and installation time.

Fuel

Compatibility

The Red Jacket 4” STP is UL-listed and approved for use with:

- 100% Gasoline

- 100% Diesel

- Gasoline blended with up to:

- 20% TAME, ETBE, or MTBE

- 15% Methanol

- 10% Ethanol

Fuel compatibility ensures suitability for both conventional fuels and commonly used blended fuels.

Key Benefits

- Reliable Fuel Flow: Consistent pressure and optimized delivery to dispensers

- Reduced Installation Time: Quick Set® adjustable length design

- Easy Maintenance: Above-ground servicing without disturbing piping or leak detection

- Enhanced Safety: Integrated pressure relief, spill prevention, and explosion-proof motor

- Lower Lifecycle Costs: Durable materials and simplified servicing reduce downtime

- Versatile Application: Suitable for a wide range of tank depths and fuel types

- Proven Technology: Backed by Veeder-Root’s global expertise and support network

+265999951680

+265999951680